recommended, otherwise non-detergent motor oil should be used as it is

compatible with nearly all materials used in the lens.

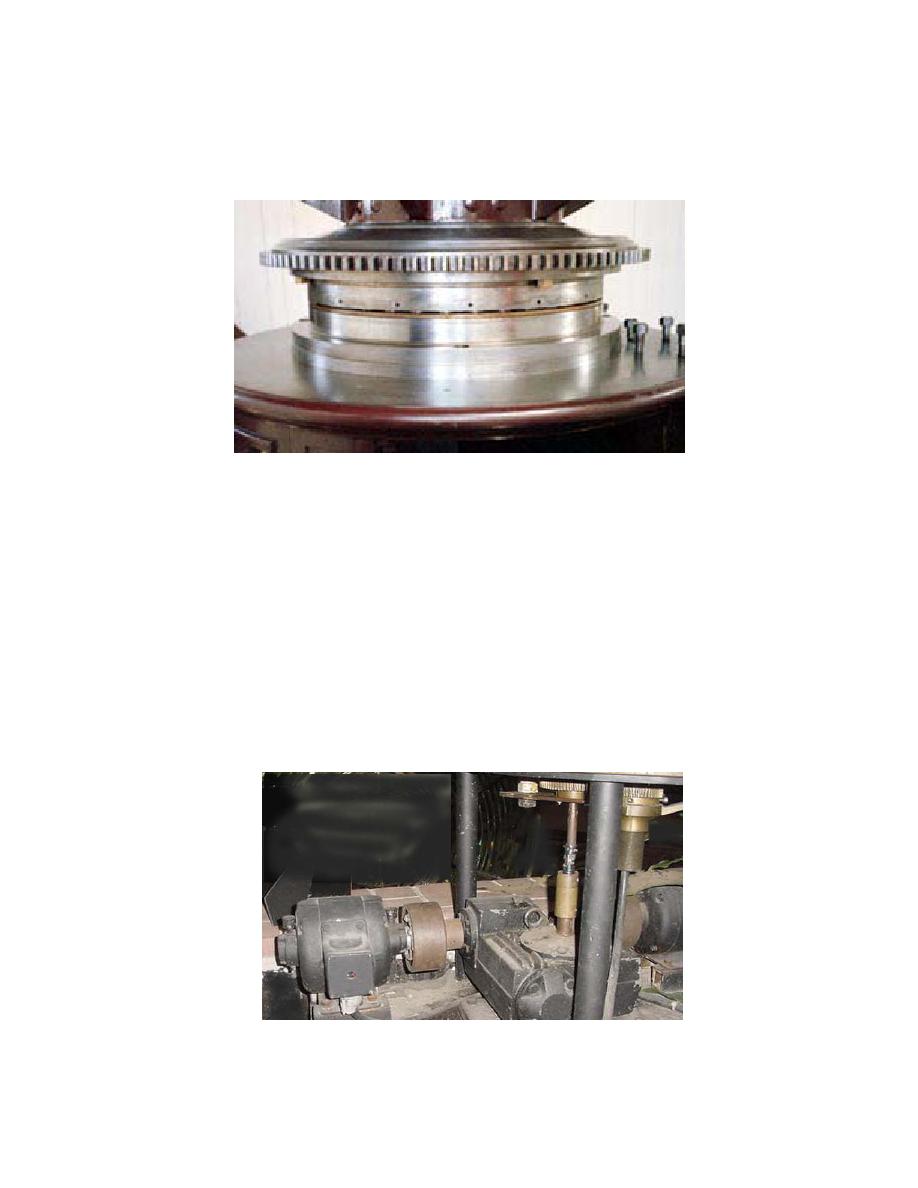

Figure 5-2. Ball Bearing Mechanism

3. Drive mechanisms are nonstandard. It is likely that a custom drive

mechanism was built after the clockwork mechanism was removed, or a

hybrid unit was constructed using old/new technology. Follow the

lubrication instructions of the motor and speed reducer detailed on the

nameplate or from documentation maintained in the aid file. Otherwise,

lubricated, but clean to prevent the accumulation of dirt. Regular cleaning

& lubrication will ensure the longevity of the components. Try to keep

spare parts at the ANT and locate a source of supply for replacements. If

none are available and the drive mechanism is failing, contact your Civil

Engineering Unit (CEU) for assistance in designing a new drive

mechanism or replacing the lens with a modern signal.

Figure 5-3. Dual Motor Speed Reducer

5-2

Previous Page

Previous Page